Processing and Manufacturing

Processing plants and manufacturing facilities suffer significant financial losses due to the failure of critical electrical assets, even from brief downtimes. Predictive and preventive maintenance tools are crucial for real-time asset monitoring to avoid such losses. Compliance with electrical safety standards is also essential. These industries often face extreme temperatures, humidity, continuous vibration, and high-duty cycles. IRISS’s Electrical Maintenance Safety Devices (EMSDs) include infrared (IR) windows, adhering to OSHA and NFPA standards for arc flash safety. These IR windows are compatible with all major thermal imaging cameras used in these facilities for fault detection.

Industries

Metals Manufacturing

With forging, stamping, forming, and machining operations, the Metals manufacturing sector is characterized by harsh environmental conditions that IRISS EMSD products were specifically developed to withstand.

Plastic Manufacturing

Electrical equipment outages in plastics manufacturing can be both costly in terms of production loss and clean-up. It can take hours to restart a plastic line after a power glitch.

Pharmaceutical

Even a brief power outage in a pharmaceutical manufacturing environment could result in huge amounts of product and raw material, for safety reasons, having to be discarded. Reliability of the electrical infrastructure in pharmaceutical manufacturing is critical.

Food and Beverage

IRISS EMSD products have been extensively deployed in food and beverage manufacturing environments. End users in this segment have been able to overhaul their thinking on how to perform condition-based maintenance by using EMSD and Critical Asset Surveillance Technologies.

Featured Case Studies

View MoreRecommended Products

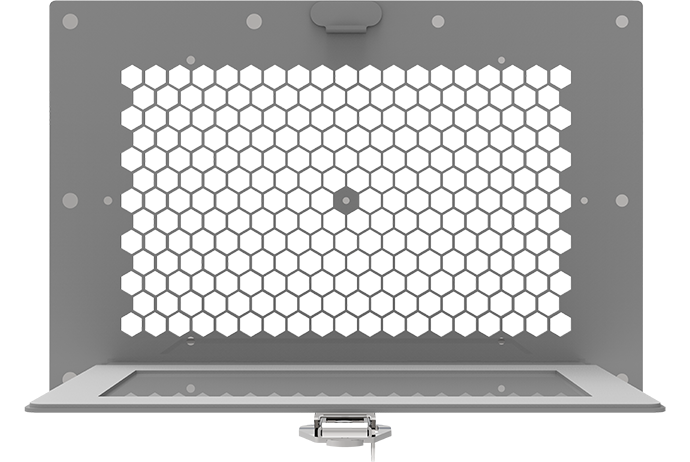

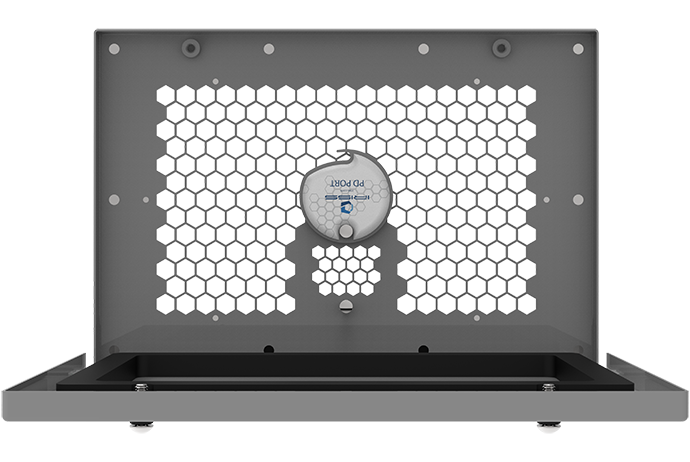

CAP-ENV-PDS Series

The Toughest and Most Reliable IR, Ultrasound & Partial Discharge Inspection Window

Starting at $449

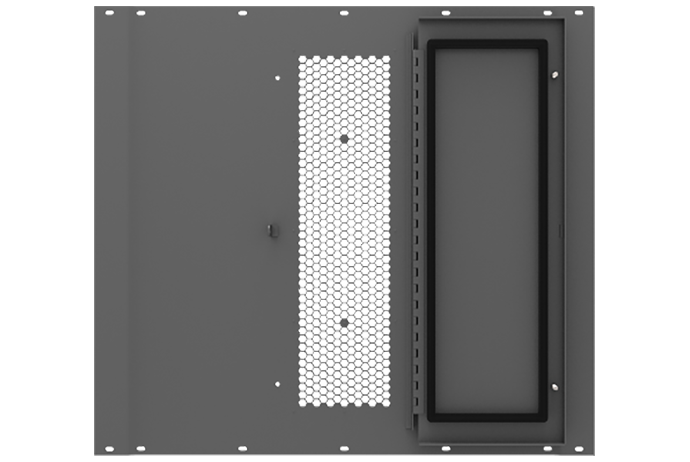

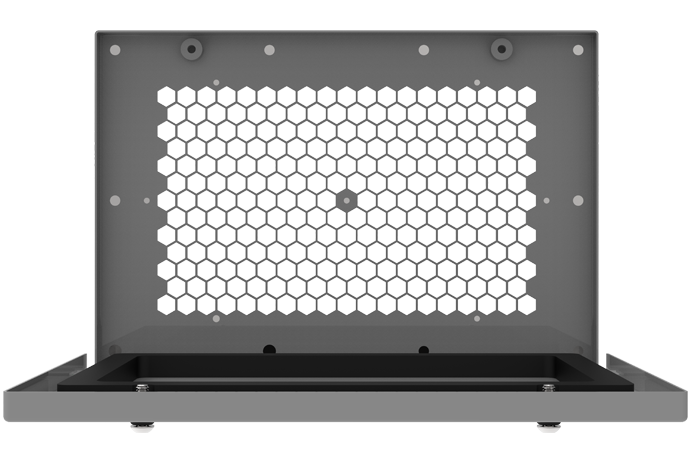

CAP-ENV-PD Series

The Toughest and Most Reliable Infrared and Ultrasound Window

Starting at $839

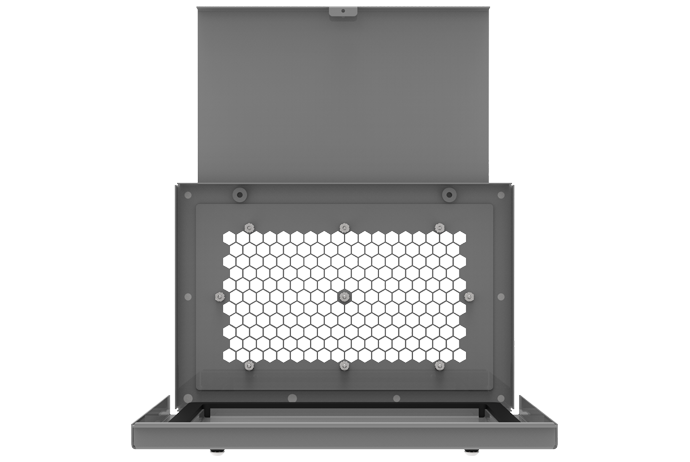

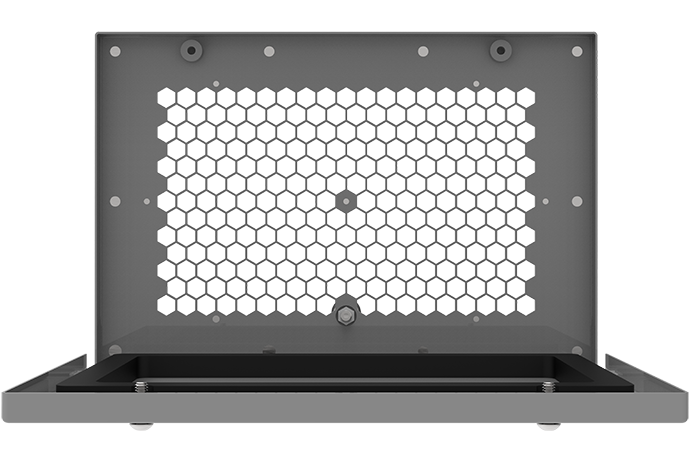

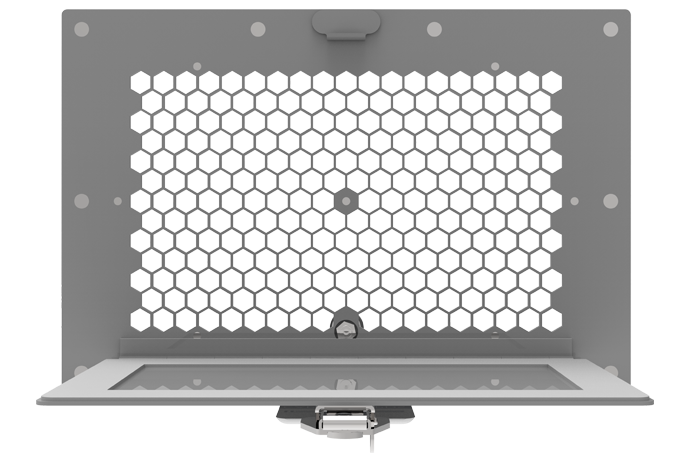

CAP-CT-PDS Series

The Most Versatile & Reliable IR, Ultrasound & Partial Discharge Inspection Window

Starting at $399