January 23, 2024

Major Middle East Utility Pilot’s use of IRISS Maintenance Inspection Systems

With more than four months per year where the maximum daily temperature exceeds 101°F (38°C), Dammam, Saudi Arabia is one of the hottest places on earth.

by Mohamed Ahmed, Level II Thermographer, IRISS Inc.

Overview

With more than four months per year where the maximum daily temperature exceeds

101°F (38°C), Dammam, Saudi Arabia is one of the hottest places on earth. In fact,

Saudi Arabia is ranked the third hottest country in the world after only Libya and

Qatar. Due to its proximity to the Persian Gulf, Dammam’s temperature moderates

slightly, but humidity levels become a secondary issue for more than half the year

with levels being described as oppressive to miserable at least one day per week.

Dust storms that last days are an issue in the region with fine sand particles

becoming airborne and permeating everything they encounter.

Into this environment, insert the utility electrical distribution equipment that must

operate reliably to ensure power service is uninterrupted for homes and businesses.

In addition, much of this utility infrastructure, like in many places around the world, is

more than 40 years old. Transformers and medium voltage switchgear in this

environment require regular condition-based monitoring to reduce the risk of failure

and Arc Flash — especially as they age.

To facilitate safer and more efficient condition-based maintenance inspections using

both infrared and ultrasound technology, an IRISS partner in the region, EEIC, recently

completed the pilot installation of Electrical Maintenance Safety Devices

(EMSD). Ten (10) CAP-ENV-12-PD rectangular combination infrared/ultrasound

inspection systems were installed on older Saudi Electricity Company (SEC)

13.8 kV utility equipment with a history of unscheduled downtime. Regular infrared

inspections can detect overloaded or loose electrical connections, while ultrasound

can be used to find signs of Partial Discharge (PD) including arcing, tracking and

corona.

The CAP-ENV-PD units deployed were custom-designed to meet the specific

requirements of SEC, which included stainless steel IP67 (NEMA 6) ingress

protection and the ability to field replace the polymer optic from the front of the

window. In addition, the units were equipped with E-Sentry intelligent asset tags,

which allows data collection to be conducted with a smartphone app, and all data

pushed to a cloud database.

Paul Goodbody of the IRISS UK office, traveled to Dammam to assist with the

installation of the pilot units and to train both EEIC and SEC personnel on how to

utilize the inspection systems for maximum benefit. Ahmad Mohammad Mosaad,

distribution engineer at Saudi Electric Company, described the pilot installation as, “A

total success that we intend to duplicate across our fleet of assets.”

Figure 1 Paul Goodbody of IRISS demonstrates how to utilize an IR window template.

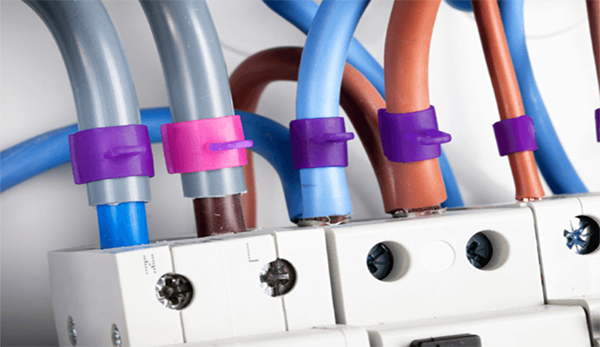

Figure 2 SEC engineer performs an infrared inspection on a transformer cable

compartment using a CAT S60 phone with a built-in IR camera and a CAP-ENV-12-

PD inspection window.

Figure 3 Paul Goodbody of IRISS listens to the airborne ultrasound signature on the

MV side of a transformer using a SONUS PD handheld partial discharge detector.