December 19, 2023

A Geothermal Energy Generation Facility Embraces Infrared Polymer Window Inspections

A prominent geothermal energy producer in the Philippines has become a leader through the successful development and operation of numerous energy projects.

by Dominique Capili, Spectrum Scientific Corporation (An IRISS Distributor)

Overview

A prominent geothermal energy producer in the Philippines has become a leader

through the successful development and operation of numerous energy projects.

Since 1983, the company has successfully developed, financed, built and operated

seven geothermal steam fields for both wet and dry steam and also owns and

operates eleven geothermal power plants. Using the company’s expertise, they seek

continual improvements to ensure the safe and efficient construction and operation

of current and future power plants.

Temperature plays a key role in the everyday maintenance and condition monitoring

processes of a power plant. Temperature is the first parameter that is monitored to

measure the health of the equipment. Maintenance professionals have been

integrating thermography into their maintenance programs to increase efficiency and

determine if the equipment is still within the allowable temperatures set by its OEM

during operation. For an effective thermographic survey, one must have a direct line of

sight exposing the surface to be measured. Previously, for an electrical inspection of a

4160-volt metal-clad switchgear, the inspector had to remove eight bolts, carefully lift

and remove the heavy steel back cover away from the panel and then later inspect it

with an infrared camera. This procedure is time-consuming, troublesome and most of

all, dangerous due to the increased risk of producing an arc flash.

Thermography is used in maintenance programs because of three unique

characteristics:

- It can be performed at a safe distance away from the hazards surrounding the

equipment without compromising the safety of the plant personnel. - Two-dimensional inspections enable the visualization of the changes in heat

patterns on the surface of the equipment. This assists in the interpretation of

“what” or “where” a fault may occur. - Real-time visualization of thermal patterns helps analyze the equipment in its

fully energized state.

Infrared polymer windows, when mounted on fully energized equipment, allow

infrared energy to pass through making thermography inspections safe and in

compliance with NFPA/CSA/OSHA or any other local safety regulations.

Inspections are completed without equipment shutdown providing real-time data

assessments of a facility’s critical assets.

Installation

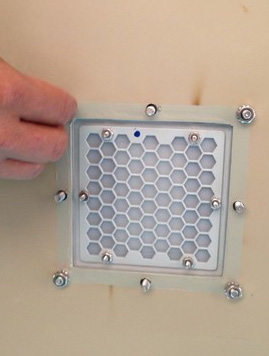

Over a period of three weeks, twenty-seven (27) IRISS Infrared Windows were

recently installed with no lost time or accidents. Due to safety concerns, the previous

site survey and visual inspection were limited to external surface temperature

measurement and visual inspection of panels with the absence of opening any doors

or covers. The preliminary installation design was based on shop drawings that

determined the quantity, size and specifications of the infrared windows needed.

During the scheduled shutdown, actual visual inspections and de-energized openings

of panels were conducted to identify and verify which components would be a main

priority for the infrared inspections. Several window sizes and exact locations were

changed once the open panel inspections were performed.

In total, twenty-two (22) CAP-C-6 and five (5) CAP-C-4 windows were installed on

twelve (12) 4.16kV panels and fifteen (15) 13.8kV panels, generators and

transformers.

Installation Photos

Pre-Installation

Post-Installation

Step 1: Lay Out

Step 2: Cutting & Drilling

Step 3: Touchup Painting

Step 4: Mounting

Equipment Testing

The last few days were allocated for bench testing, simulation of readings using

multiple OEM IR camera types and training of personnel. The simulation of readings

using the various camera types and a Black Body temperature source through the

IRISS infrared polymer windows measured distance-corrected ambient temperature,

emissivity usage values and parameter settings on the respective devices.

Bench Testing

Black Body Simulation

Where possible, connections were taped with known emissivity insulating tape. In

this way, more accurate temperature readings can be taken of the target potential

hot spots.

Emissivity Tape Mounting

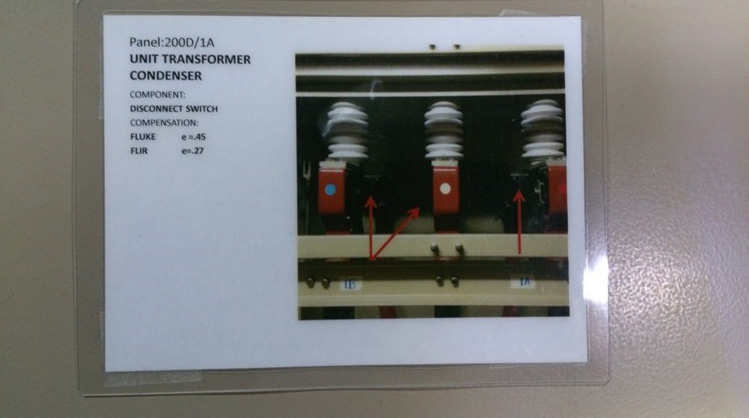

As an opaque polymer optic was used on this project, digital photos were taken,

laminated and then placed adjacent to the respective inspection window. Target

locations for IR inspection were included on the digital image as well as the proper

transmission rate for each camera type that might be used by the inspector. In this

way, the future IR inspector will have a better idea of what they are looking at with the

IR image and it will ensure consistent and accurate temperature data collection

methods.

Labelling

Conclusion

Since the initial IR Window installation, the program has helped the inspection team

decrease the time required to conduct inspections as it does not require a “hot

work” permit and can be done by a single person with no need for special personal

protective equipment (PPE). As of publication of this document, they have not found

any serious faults but have observed some slight temperature rise on some assets

that are being trended and monitored for future change. Plans are being made to

expand the use of IR windows on other equipment at this site as well as other

power plants owned by the power producer.