Infrared Inspection Solutions

Safely Inspect Your Electrical Assets in an Energized State

Infrared inspection Solutions such as IRISS’s infrared windows and handheld cameras are essential for safety and reliability. These non-invasive tools efficiently monitor electrical systems, preemptively identifying issues to prevent failures. IRISS stands out with its patented polymer technology in infrared windows, ensuring durability and optimal performance. Their custom-sized infrared window solutions offer tailored designs for diverse electrical systems, elevating the effectiveness of inspections. Using innovative technology and customization positions IRISS’s products as crucial for ensuring ongoing safety and reliability.

View MoreThermal Performance Monitoring

Employs thermal imaging to detect and visualize temperature variations in equipment and structures, identifying hot spots, insulation failures, or electrical issues that could lead to safety hazards or operational inefficiencies.

Preventive Maintenance Tool

Facilitates early detection of potential problems by revealing areas of excess heat caused by friction, electrical resistance, or blockages, allowing for timely maintenance actions before costly breakdowns occur.

Non-Contact and Non-Invasive

Allows for the inspection of machinery and infrastructure without direct contact, minimizing the risk to inspectors and avoiding disruption to ongoing operations, ensuring continuous productivity.

Features

Enhanced Visibility

Offers clear visibility into critical electrical components without the need to open enclosures, maintaining safety standards.

Easy Integration

Can be easily integrated into existing electrical maintenance routines, complementing other safety and maintenance practices.

Technology Utilization

Utilizes advanced IR inspection technology to detect issues that are not visible to the naked eye, such as overheating components.

Long-Term Reliability

Provides a reliable solution for continuous monitoring of electrical systems, contributing to the longevity and reliability of electrical assets.

Infrared Inspection Solutions

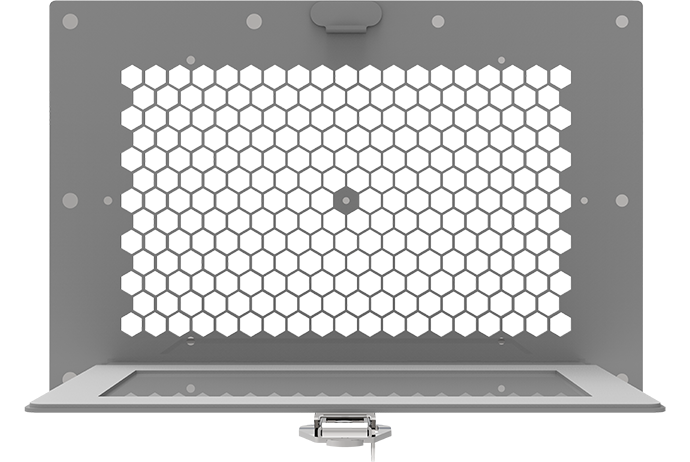

QwikFit-IR

It’s Time Your Infrared Window Fitted Your Needs and Applications

Starting at $ 104

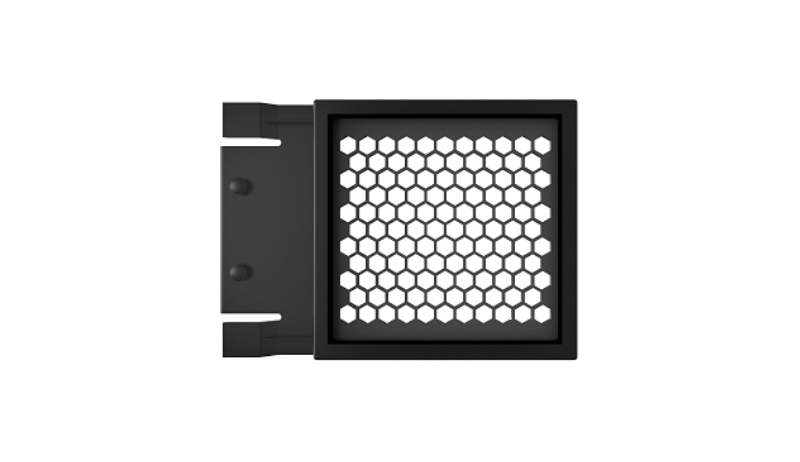

HIKMICRO G60 Series

Bigger Touch Screen Camera with Optical and Thermal Images

Starting at $ 6999

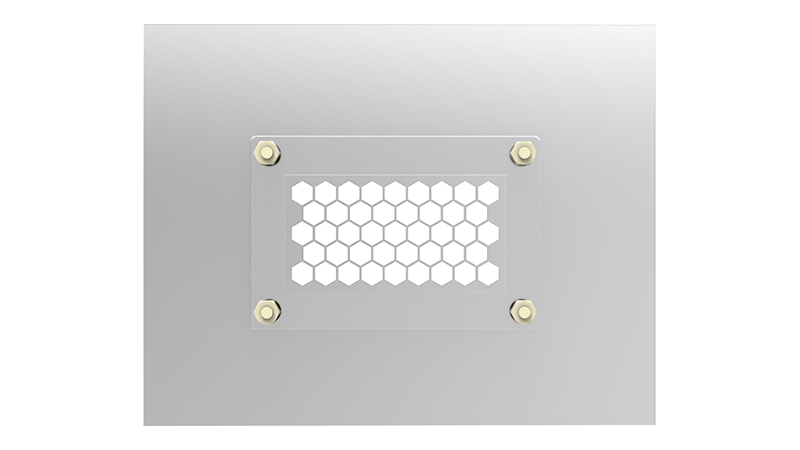

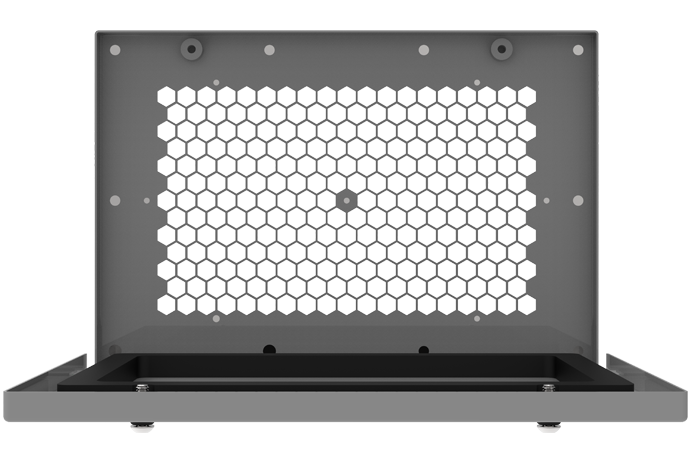

VP-12-IR Series

Because Sometimes a Smaller Infrared Window Is All You Need

Starting at $ 89

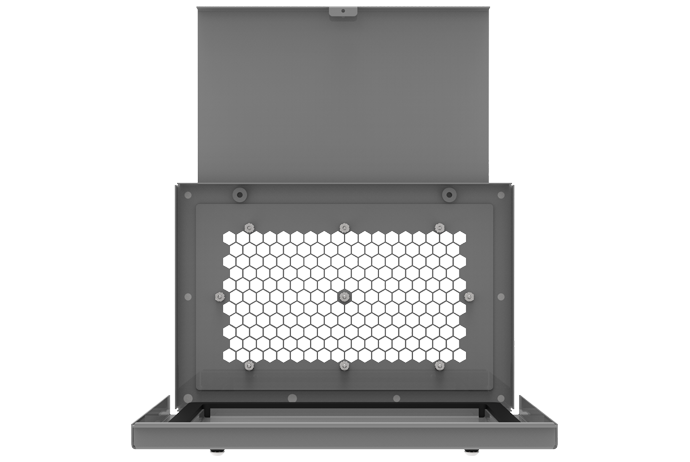

CAP-ENV Series

The Toughest and Most Reliable Infrared Window in The World

Starting at $ 399