Mines provide the critical raw materials needed by our agricultural and manufacturing sectors. The first-level metal processing facilities, including ore processing, smelting operations, steel, copper, and aluminum mills, and casting and forging facilities, all use huge amounts of electricity to power the process equipment. The environmental conditions in these facilities can be severe and require robust equipment solutions. Airborne contaminants are always a concern, and electrical infrastructure should be inspected at regular intervals. In addition, mining operations are governed by MSHA safety rules, which are even more strict than OSHA guidelines.

Under Ground Mining

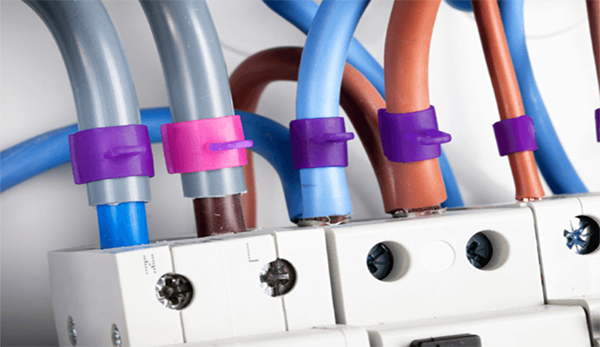

Mining operations often use portable power sleds with switchgear and transformers mounted. The fact that these are moved frequently and that power connections are shifted around increases the probability of a loose electrical connection. EMSDs allow you to find and fix these small problems before they become equipment failures.

Electric Shovels

Similarly to cranes in port applications, mining shovels are primarily now electrically operated. A shovel outage can cost thousands of dollars per hour and starve the ore processing facility. Regular inspections of the shovel’s electrical systems are critical but can only be done safely when EMSDs have been implemented.

Strip Mining

IRISS EMSDs have been installed extensively in phosphate and other strip mining applications and were specifically developed for these harsh environments where dust, moisture, vibration, and even caustic contamination would destroy a traditional crystal infrared window.

Fixed and Mobile Assets

From Rock Crushers to separators to electrically driven super-sized dump trucks, the mining sector relies on many different devices to keep raw materials flowing. IRISS has installed infrared windows and other EMSDs on these devices to ensure reliability.