by Karen Fox, CRL, LV 1 Thermographer, LV 1 Airborne Ultrasound

John Zyznomyrsky, CRL, LV II Thermographer, LV 1 Airborne Ultrasound

Overview

One of North America‘s leading bottled water companies dedicated to providing

customers with healthy hydration options and equally committed to keeping their

people safe recently approached IRISS for assistance in optimizing their asset

life cycles. Their primary goal was to define cost-effective, consistent maintenance

processes by adopting the technologies to support and sustain these processes

throughout the U.S. and Canada. As part of this multisite initiative, one of IRISS‘

distributor partners, Scott Thornton of DTM Consulting Services, was engaged

to provide recommendations for placement, sizing and type of IR windows to be

installed at their Ontario, Canada facility. After an initial site survey, DTM

recommended the CAP-CT series in various sizes to complete this project. CAP-CT

series is a NEMA 4 / IP65 rated IR window and is ideal for indoor applications.

Standard sizes are 4, 6, 12, 18 and 24 inches plus custom sizes are available

including optional partial discharge ports.

Analysis of Inspection Program

The company developed a reliability and maintenance policy that includes a three to

five-year improvement plan. This policy was then communicated to all employees.

The company outlined all essential reliability and maintenance elements, their key

performance indicators, why these are important and the importance of Reliability

Centered Maintenance (RCM) and Reliability Based Maintenance (RBM) program for

overall plant safety.

The company had done the necessary research and determined that they would

retrofit using the IRISS transparent patented polymer Infrared Windows as a safer

method of conducting standards-compliant inspections. It was decided by the

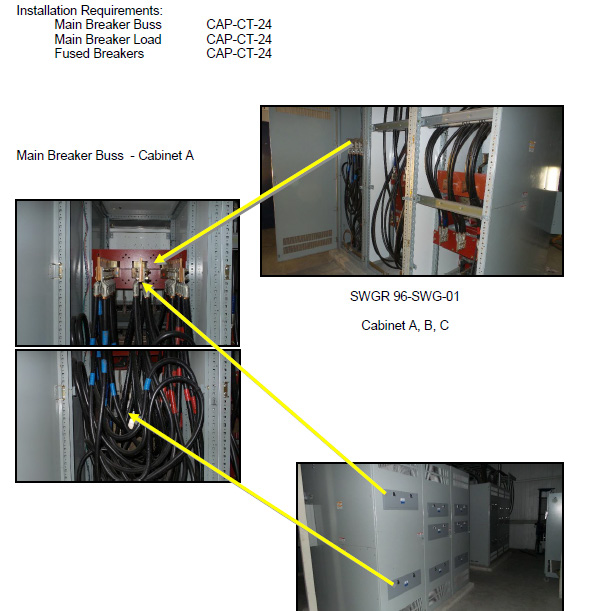

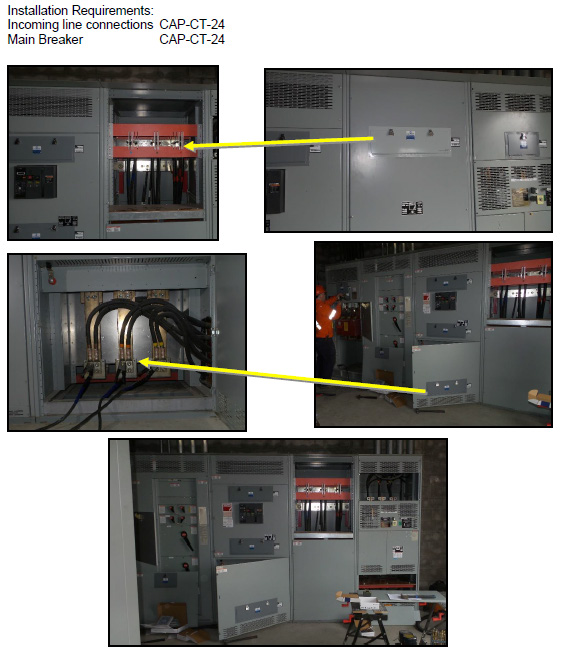

reliability team to implement the large format infrared polymer windows for the Main

Switchgear Bus connections, Main Breaker connections and Fused Switches to help

eliminate the hazard of live work by finding hot spots through the IR windows.

As a result, more frequent inspections of energized equipment could be performed

by retrofitting with Infrared Windows for routine inspections. The closed panel

inspections with the windows in place did not require elevated levels of Personal

Protective Equipment (PPE) mandated in NFPA 70E, thus reducing time and

maintenance costs. Thermal imaging was not new to the maintenance and reliability

team as they had previously retrofitted some equipment with traditional round

calcium fluoride windows. However, it was determined that a transparent polymer

Infrared Window available in various large formatted sizes would provide both visual

and thermal inspection with fewer units needing to be installed.

The IRISS patented polymer-based infrared windows are unaffected by the

environmental and mechanical stresses ensuring that the temperature data collected

through the IRISS IR window is accurate and reliable for the whole life of the

installation. Crystal-based IR windows are both highly fragile and hygroscopic (even

when coated) causing degradation of the transmission over time and temperature

reading errors. Polymer-based IR windows are far more able to resist the mechanical

stresses applied to IR windows that are fitted to electrical distribution equipment.

IRISS industrial-grade IR windows meet mandatory impact and load testing

requirements of UL, CSA, IEEE and IEC. Many of these tests cannot be passed by any

crystal-based IR window.

With the infrared windows installed, there was no need to remove panels or wear

increased levels of PPE. Inspections could now be performed more often and on

electrical equipment that had previously been considered “uninspectable” due to high

levels of Arc Flash incident energy.

The installation process proceeded smoothly and included:

- Pre-planning to identify the equipment and obtain approval to shut down.

- De-energizing the equipment with two electricians to make sure it was safely

isolated, locked out and tagged out. - Once de-energized, the two electricians removed all covers on the equipment in

question. - The IR windows were installed using supplied drill/cut templates in the

appropriate location and the covers were replaced. - Appropriate PPE was put on by the electricians and the equipment was

reenergized. - Together with operations, the electricians confirmed the equipment was operating

at normal load levels and allowed sufficient time for the equipment to become

thermally stable. - The thermographer electrician then performed the infrared inspection on the

equipment to secure baseline temperature data. - Personnel completed the inspection by taking notes of any problems discovered.

Results

The bottled water company has recognized huge savings in time and money with

the implementation of IRISS patented transparent polymer infrared windows into

their condition-based monitoring program. The use of polymer infrared windows

allows more convenient and frequent inspections resulting in the ability to catch and

fix potential problems long before they turn into unexpected outages. In this way, the

bottled water locations will see increased Mean Time Between Failure (MTBF) on

their critical electrical infrastructure. Most large facilities with large distribution

power systems find that their insurance provider requires annual infrared (IR)

inspections of their electrical systems. This mandate is a direct result of verbiage

found in NFPA 70B but retrofitting IR windows enables the facility to perform these

inspections in a fraction of the time and in a much safer way.

Based on the results at the first sites, the bottled water company has now

proceeded with the implementation of the IRISS IR window solutions at twenty-nine

(29) of their sites around North America.