Meet the New Standard in High-Temperature Inspections

Industrial systems in high-temperature environments demand robust solutions for monitoring and maintenance. Whether it’s a furnace operating at 1832°F (1000°C) or an industrial oven in constant use, maintaining safety, efficiency, and equipment longevity is critical.

IRISS is proud to introduce the CAP-HT-100 Series, a groundbreaking line of inspection windows engineered specifically for extreme environments. These innovative tools allow technicians to safely and efficiently perform high-temperature inspections, offering compatibility with infrared thermography and Gold Cup inspections to address the unique challenges of these conditions. By incorporating cutting-edge features, they ensure accurate temperature readings and reliable performance in extreme environments.

The CAP-HT-100 Series represents the next generation of inspection technology, designed to help industries achieve safer, smarter, and more reliable operations.

The Challenge of High-Temperature Inspections

High-temperature environments create unique challenges for equipment monitoring and maintenance. Over time, thermal stress can degrade materials, accelerate wear, and increase the likelihood of failures. Traditional inspections often involve shutting down systems—disrupting operations—or exposing technicians to dangerous conditions.

Accurate temperature readings and precise temperature measurements are also difficult to achieve in such environments. Reflective surfaces, emissivity variations, and extreme heat can distort data, making it harder to detect temperature patterns or inefficiencies. Tools like Gold Cup inspections, designed for localized temperature accuracy, and durable inspection windows, which provide sealed monitoring capabilities, are essential for overcoming these hurdles.

Gold Cup Inspections: Precision Redefined

Gold Cup inspections offer a specialized approach for measuring temperature and achieving accurate temperature readings in high-heat environments. By using a concave reflective surface, Gold Cup tools shield sensors from external light and environmental interference, delivering highly accurate temperature readings even on reflective or non-uniform surfaces.

Gold Cup inspections are critical for industries like metal forging and glass manufacturing, where maintaining specific temperature ranges directly impacts product quality. By integrating this technology into maintenance routines, facilities can improve process reliability while minimizing risks.

Introducing the CAP-HT-100 Series Models

Each product in the CAP-HT-100 Series is engineered to address specific inspection needs, from broad thermal imaging to pinpoint temperature accuracy, ensuring reliable performance for detecting temperature patterns and maintaining specific temperature ranges. Here’s a closer look at the capabilities and applications of each model.

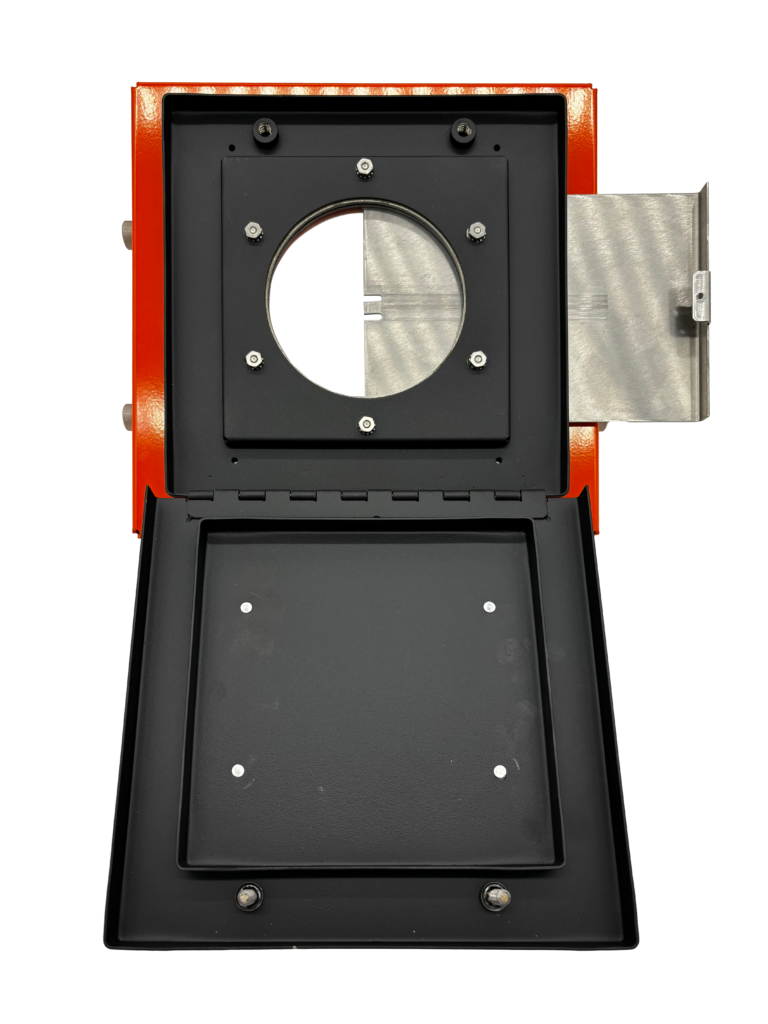

CAP-HT-100: Reliable Infrared and Visual Inspections

The CAP-HT-100 is a foundational tool for high-temperature environments, providing safe, efficient monitoring for systems operating under extreme heat.

Inspection Types Permitted:

- Infrared Thermography: Detects temperature patterns using shortwave (SWIR) and midwave (MWIR) IR spectrums.

- Visual Inspections: Offers clear viewing for quick assessments of enclosed systems.

Key Features:

- Sapphire crystal lens for superior clarity and durability.

- Withstands surface temperatures up to 1832°F (1000°C).

- Durable stainless steel body with NovaMica HiTemp gaskets.

Use Case: Perfect for routine monitoring of furnaces, ovens, refractory ovens, and heating systems, enabling technicians to perform inspections without exposing themselves to extreme heat or shutting down equipment.

CAP-HT-100-P: Precision with Gold Cup Inspections

The CAP-HT-100-P is purpose-built for Gold Cup inspections, delivering localized temperature accuracy in high-heat conditions.

Inspection Types Permitted:

- Gold Cup Inspections: Provides shielded, precise temperature readings, even on reflective surfaces.

Key Features:

- Exclusive compatibility with Gold Cup tools for enhanced accuracy.

- Robust stainless steel construction with a high-temperature powder coating.

- Dust-resistant sliding covers for long-term reliability.

Use Case: Ideal for industries like metal smelting and glass production and refractory ovens in the petrochemical industry, where precision temperature measurements are critical for maintaining process quality and safety.

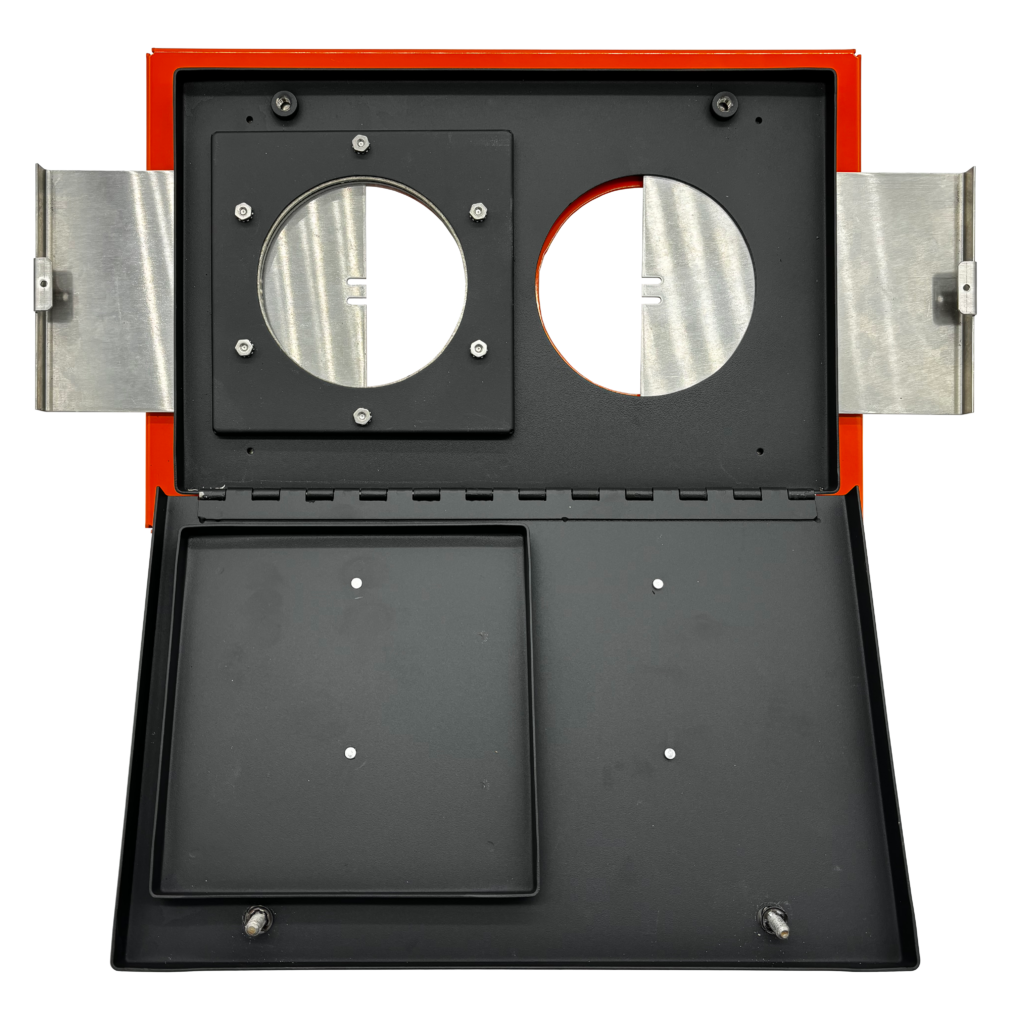

CAP-HT-100-AP: The Dual Solution

Combining the capabilities of infrared thermography and Gold Cup inspections, the CAP-HT-100-AP is the most versatile model in the series.

Inspection Types Permitted:

- Infrared Thermography: Provides comprehensive thermal imaging for pattern detection.

- Gold Cup Inspections: Enables accurate localized temperature readings.

- Visual Inspections: Offers clear, unobstructed views for quick diagnostics.

Key Features:

- Larger aperture for expanded inspection coverage.

- Dual compatibility with infrared cameras and Gold Cup thermometers.

- Durable construction with sapphire lenses and NovaMica HiTemp gaskets.

Use Case: A flexible solution for multi-stage manufacturing processes, allowing technicians to perform both broad thermal assessments and precise localized measurements without compromising safety or efficiency.

Enhance Safety and Reliability with Predictive Maintenance

The CAP-HT-100 Series is a cornerstone of modern predictive maintenance strategies for high-temperature environments. By enabling consistent, non-invasive inspections, these tools help facilities:

- Identify inefficiencies and potential issues early.

- Reduce the risk of unplanned downtime with scheduled, reliable monitoring.

- Enhance safety by minimizing exposure to extreme heat and hazardous conditions.

With support for both infrared thermography and Gold Cup inspections, the CAP-HT-100 Series equips technicians with innovative tools to monitor equipment effectively, achieve precise temperature accuracy, and maintain operational excellence.

Explore the Future of High-Temperature Inspections with CAP-HT-100

The launch of the CAP-HT-100 Series marks a new era for high-temperature inspections. These innovative tools provide the precision, durability, and safety that industries need to thrive in extreme environments. Whether you’re looking to perform infrared thermography, Gold Cup inspections, or both, the CAP-HT-100 Series offers a solution tailored to your needs.

Explore the CAP-HT-100 Series today and discover how it can transform your high-temperature inspection strategy.