Description

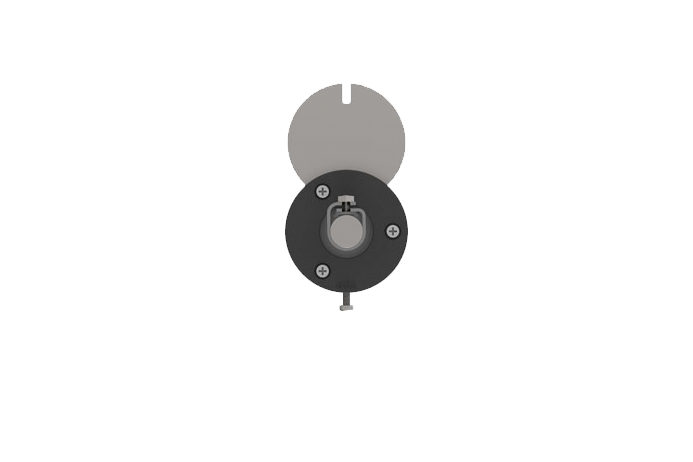

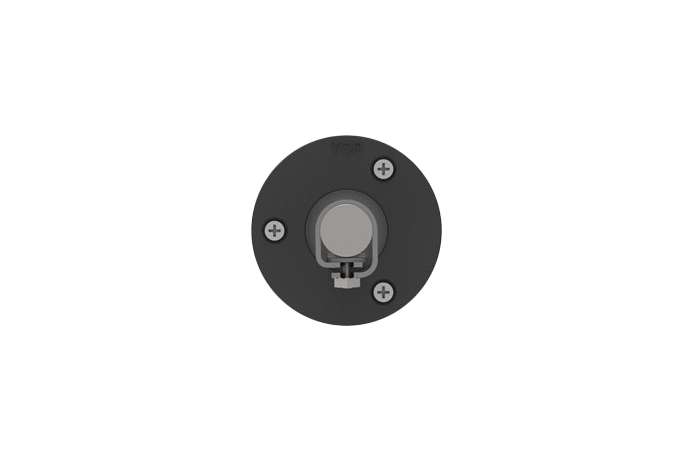

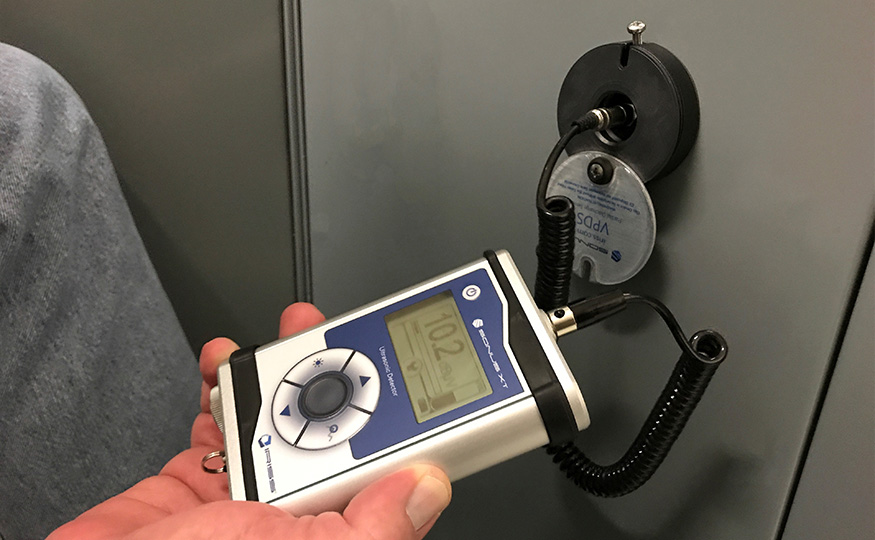

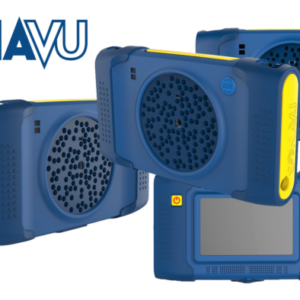

The VPDS Ultrasound Sensor is the most effective and safest way to perform ultrasound inspection on energized electrical assets from low to high voltage. Ultrasound electrical inspection has been relegated to scanning the seams and opening of electrical assets for years. Oftentimes, the inspector runs into antagonistic ultrasound from other sources, limiting the inspector from achieving the critical angle of the incident wave to analyze the best sound wave. To improve the effectiveness and safety of the ultrasound inspector, IRISS designed the first Ultrasound Sensor that is mounted in the panel with a transducer on the inside facing the gear. With its 3.5 mm headphone jack, almost every make and model of ultrasound testing device can plug in and listen to the gear safely from the outside. This allows the inspector to quickly identify the existence of potentially hazardous faults such as corona, treeing, tracking, delamination of windings and loose connections.