Ultrasound Inspection Solutions

Beyond Heat: Ultrasound Solutions for Next-Level Reliability

Ultrasound complements visual inspection and infrared thermography for a comprehensive assessment of equipment condition.

Ultrasound technology revolutionizes electrical and mechanical inspections by detecting faults before they generate heat. Ultrasound identifies arcing, tracking, and corona in any environmental condition. When paired with infrared thermography and visual inspections, ultrasound provides a complete view of system health, confirming thermal anomalies and ensuring early detection. IRISS ultrasound windows enable inspectors to combine the strengths of both technologies for a thorough, precise, data-driven assessment of asset condition.

What Makes Ultrasound a Must Have

for Electrical Inspections?

Early Fault Detection

Ultrasound enables inspectors to identify arcing, tracking, and corona discharge before they generate heat, addressing issues earlier than infrared alone.

Enhanced Safety

Ultrasound- embedded IRISS windows eliminate the need to open energized panels, reducing arc flash risk and ensuring safer standards compliance.

Improved Accuracy

Combine ultrasound and infrared data to cross-verify findings, detecting issues before heat develops and confirming thermal anomalies for a full fault profile.

Fully Certified

UL Listed (E491496) and arc flash-rated, IRISS ultrasound windows meet and exceed rigorous safety standards, ensuring compliance and performance in the most demanding environments.

Unmatched Warranty

Backed by the industry’s only unconditional lifetime warranty, these windows are designed to outlast your asset.

Increased Efficiency

Streamline your workflow with single-access windows for both ultrasound and infrared, saving time and consolidating inspection teams down to one.

Predictive Maintenance Tool

By enabling comprehensive inspections, ultrasound ports help reduce fire risk, unplanned outages, and equipment failure, extending equipment lifespan through proactive maintenance.

Need help? Want more information?

No matter the size of your organization, we’ll work with you to create the perfect plan that aligns with your goals and budget. Explore how IRISS solutions can transform your operations by providing unparalleled features and benefits. Contact us today to get started with a personalized quote!

Safely Inspect Your Electrical Assets in an Energized State

Ultrasound inspection using sound ports and handheld testing devices plays a critical role when used in asset inspection and management programs. Anomalies in equipment or components of equipment may create ultrasound waves that, when detected, could alert the maintenance team that a component needs to be further assessed for deterioration. The goal is to find the anomaly, determine the health of the equipment, and fix it if needed before that equipment fails. Condition Based Maintenance programs allow teams to proactively detect and fix defects before costly repairs or full replacements are needed.

Enhanced Diagnostic Accuracy

Utilizes partial discharge sensor sound ports and handheld devices to accurately pinpoint the source of equipment anomalies for precise diagnostics.

Minimizes Downtime

By detecting issues early, it significantly reduces the risk of unplanned downtime, enhancing operational efficiency.

Sustainability in Maintenance

Promotes a sustainable approach to maintenance by extending the life of equipment and reducing the need for resource-intensive replacements.

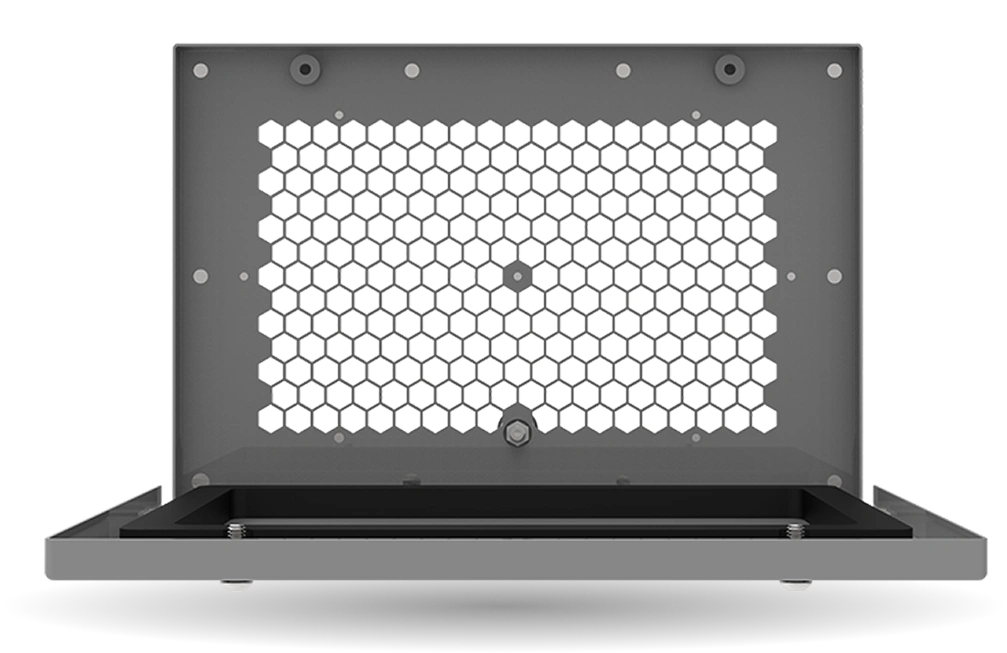

The Toughest & Most Reliable Inspection Windows

The CAP Series by IRISS delivers unmatched precision, safety, and versatility in electrical asset monitoring. Designed for the power generation sector, the CAP-B features a large-format window for infrared, visual, and UV inspections on non-segmented bus bars, ensuring comprehensive diagnostics. The CAP-CT, equipped with the exclusive Poly-View System™, provides an expansive IR viewing area for seamless multi-spectrum monitoring, while the CAP-CT-PDS integrates Thermal Imaging, Visual, UV, Ultrasound, and Partial Discharge detection for a holistic approach to condition-based maintenance. For added durability, the CAP-ENV features an environmentally sealed door with an optional dust cover, protecting critical assets in harsh environments. With the CAP Series by IRISS, maintenance teams gain the clarity, safety, and efficiency needed to optimize inspections and enhance reliability.

Look & Listen Simultaneously

Quickly and safely perform closed panel inspections of electrical equipment with infrared and ultrasound.

Arc Containment Tested

The CAP-ENV-PDS Series was successfully tested to the IEC 62271-200 standard for arc containment on metal enclosed switchgear assemblies.

Improve Your Vision

The large format IRISS CAP series and custom infrared windows have a far superior field of view when compared to traditional round windows.

Transparent Polymer Ultrasound Window

The VP Series by IRISS redefines predictive maintenance with advanced solutions for ultrasound and infrared (IR) inspection, ensuring safer, more reliable asset monitoring. The VPDS Ultrasound Sensor enhances energized electrical inspections with an in-panel transducer for superior safety and detection, while the VPT Series IR Windows, featuring our exclusive Poly-View System™, enable seamless thermographic monitoring with any infrared camera. The VP-12-US Acoustic Sensor standardizes ultrasound data collection, delivering consistent, high-quality results regardless of technician experience or enclosure rating. Designed for condition-based maintenance (CBM) programs, the VP, VPT, and VPFC Series provide unparalleled safety, accuracy, and adaptability, empowering maintenance teams to reduce risk, optimize performance, and extend asset life.

Arc Safety Tested

Successfully tested to the IEC 62271-200 standard for arc containment on metal-enclosed switchgear assemblies to help protect workers from injury or fatality.

Patented Design

Our exclusive polymer technology is unaffected by environmental stresses and enables visual, IR, and UV inspections across the entire infrared spectrum.

UL Listed

Having passed rigorous standards and testing, our inspection windows are UL Listed (E491496). This demonstrates our dedication to continued safety and security.

Schedule a site visit to see how IRISS can transform your approach to safety and asset management.

Experience firsthand how IRISS is revolutionizing electrical maintenance safety while supporting your organization’s short- and long-term reliability and sustainability goals. A site visit or personalized demo is the best way to explore our innovative engineered inspection solutions, from Electrical Maintenance Safety Devices (EMSDs) to enterprise asset management systems. See how our cutting-edge products are designed to protect your people, equipment, and operations while enhancing reliability, reducing risks, and simplifying processes. Discover how our tailored solutions not only improve safety but also align with your sustainability objectives by promoting efficient and resilient operations. Don’t just take our word for it—schedule a site visit or demo today and see why IRISS is the trusted leader in safety, innovation, and sustainable reliability. Let us show you how we can redefine safety for your organization.

Stay ahead with our electrical safety insights

Get the latest news, product updates, trade events, case studies and more in your inbox from IRISS.

Subscription Form

"*" indicates required fields

Do you have any questions?