Offshore Drilling Company Reaps Big Savings with FlexIR Windows

In this article:

by Jason Bricker, Level 1 Thermographer, IRISS Inc.

Overview

Recently, the chief electrician of a large offshore drilling company realized the

problems his staff were having performing safe and efficient infrared inspections on

their electrical equipment. In order to comply with the corporate safety policy for

mandatory inspections on the drillship, he hired multiple consultants to explore

faster and safer alternatives. Ty Keeth, Level III Thermographer, IRISS Certified

Installer, representing Offshore Inspection Group, was from one of the companies

attempting to solve the problem.

After Ty analyzed the electrical equipment on the drillship, he quickly realized that

there were only visual viewing windows and no sign of any infrared inspection

windows. According to Ty, “There are a unique set of problems on a drillship with the

main concerns being the safe and reliable operation of power distribution assets on

the ship. It is a major undertaking to turn off equipment.” As a result, any inspections

take a considerable amount of manpower and time.

At the time Ty was contacted, the process for one inspection involved:

- Preplanning stage to identify the equipment and obtain approval to shut down.

- De-energizing the equipment required two electricians to make sure it was safely

isolated, locked out and tagged out. - Once de-energized, the two electricians removed all covers for inspection on the

equipment in question. - Once the covers were removed, approval to re-energize and operate the

equipment was obtained, and locks and tags were removed. - Appropriate PPE was put on by the electricians, and the equipment was reenergized.

- Together with operations, the electricians confirmed the equipment was operating

at normal load levels and allowed sufficient time for the equipment to become

thermally stable. They then performed an infrared inspection of the equipment. - Personnel then completed the inspection, taking any notes of problems

discovered. - Electricians de-energized the equipment again following lock-out, tag-out

procedures and, when safe, put the equipment panels back in place. - Finally, electricians re-energized the equipment.

With this complex process, the time involved in performing an inspection on

one electrical asset was between four to six hours.

The drillship had six thruster transformers, six mud transformers, six drilling

transformers and 66 high-voltage switchgear cabinets. There were approximately 30

different types of equipment needing to be inspected. Due to the volume, the existing

inspection process took three to five people between two to three weeks to perform.

Another consulting firm suggested that standard 6-inch IR windows be installed in

front and back of the heavy switchgear equipment, but this would require multiple

significant modifications to the existing panels that would be both time-consuming

and could jeopardize the enclosure integrity.

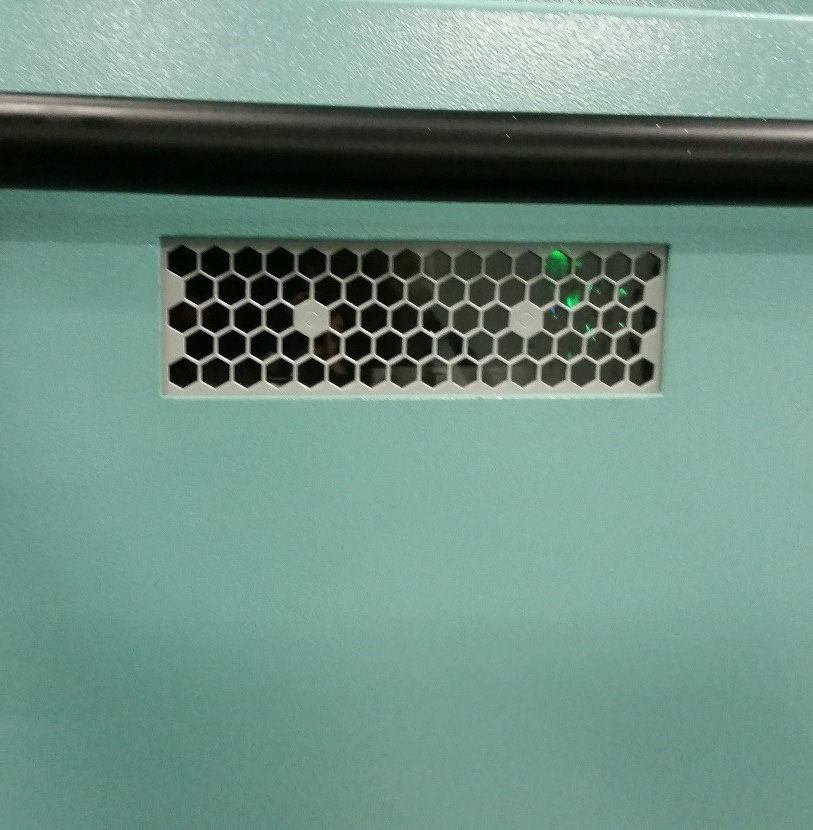

The better solution was proposed by Ty Keeth. He took the time to analyze how

the IRISS FlexIR Custom Windows could be a bespoke design to require negligible

enclosure modifications and save the company both on installation labor and IR

window procurement cost. He was able to accomplish this by replacing the existing

visual viewing windows in the switchgear with the IRISS FlexIR Custom Windows that

allow both infrared inspection and visual inspection through the clear reinforced

polymer optic.

The cost-benefit of performing the infrared inspections was phenomenal. The total

inspection time was reduced to one person inspecting all equipment over three to

five days. Over 90% of the inspection labor hours were eliminated by implementing

the IRISS FlexIR Custom Windows. It’s estimated that the IR window investment was

paid for within two inspection cycles after installation.

Related articles

Need help? Want more information?

No matter the size of your organization, we’ll work with you to create the perfect plan that aligns with your goals and budget. Explore how IRISS solutions can transform your operations by providing unparalleled features and benefits. Contact us today to get started with a personalized quote!