PDS Series

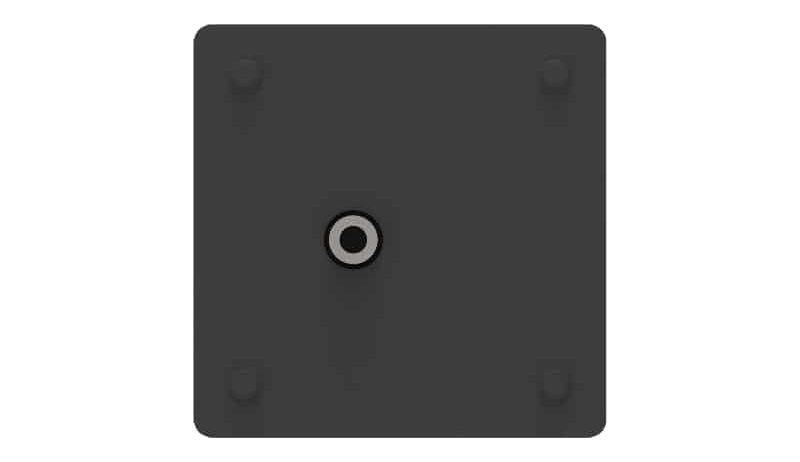

Partial Discharge Sensor Port

Partial Discharge Sensor Ports (PDS) are used in conjunction with a handheld Ultrasound measurement device, allowing the end user to take closed-panel Ultrasound decibel readings and listen to the audible signals coming from a piece of equipment. In this way, problems like Arcing, Tracking and Corona can be detected without the need for maintenance personnel to wear PPE. The PDS is a small square plate with no cover with an IP10 (NEMA1) rating and has a 3.5mm female adapter for connection to a handheld ultrasound. Note that a special adapter cable may be required depending on the brand and model of the handheld being used. Adapter cables for SONUS-XT and SONUS-PD are available from IRISS. Increase your Reliability with our technology.

Safety Without PPE

The PDS gives inspectors the ability to safely perform closed panel energized inspections, removing the need to open the gear and dress in full, heavy PPE.

Listen Through Panels

Quickly and Safely perform closed panel airborne Ultrasound inspections of electrical equipment including Switchgear, Switchboards, Panelboards, Transformers, Motor Control Centers and Process Equipment Panels.

Save Time and Money

With the installation of these ports the inspector has the ability to use a single point to listen into the cabinet instead of tracing the seam and removing any diffraction of signal that may occur.

Features

Embedded 40KHz Airborne Ultrasonic Transducer

Quickly and Safely perform closed panel airborne Ultrasound inspections of electrical equipment including Switchgear, Switchboards, Panelboards, Transformers, Motor Control Centers and Process Equipment Panels. Through the PDS’ embedded 40KHz Airborne Ultrasonic Ceramic Transducer with 3.5mm jack socket compatible with IRISS PD and TEV testing devices such as the Sonus XT & Sonus PD to detect early warning signs such as Arcing, Tracking, Corona and Partial Discharge.

Unconditional Lifetime Warranty

The IRISS Unconditional lifetime warranty is unique in the IR industry as it not only applies not only to the workmanship of the window housing but also applies to the durability and stability of the optic in the proposed environment. No other manufacturer can offer this because crystal optics will fail over time, and are only able to at best offer a limited lifetime warranty for manufacturing defects

Enhanced Reliability

The use of PDS and its compatibility with Ultrasound measurement devices contribute to enhanced equipment reliability by allowing early detection of potential issues, reducing the need for PPE, and promoting preventive maintenance, ultimately increasing overall system reliability.

IP Rating

PDS is equipped with an IP10 (NEMA1) rating, indicating its protection against solid objects and ensuring durability in various environments. This rating signifies that it offers basic protection against ingress of small foreign objects.

Specifications

| Model | PDS |

|---|---|

| General Specifications | |

| Overall Height | 7.62 cm (3 in) |

| Overall Width | 7.62 cm (3 in) |

| IP/ NEMA Environment Rating | IP10 / NEMA 1 |

| Operating Temperature | -40°C (-40°F) to 273°C (523°F) |

| Body Material | Powder Coated 5052 Aluminum |

| Gasket Material | UL 94 5VA TPE; -40°C (-40°F) to 273°C (523°F) |

| Hardware Material | 316 Stainless Steel |

| Voltage Range | Any |

| Automatically Grounded | Yes |

| Ultrasonic Receiver Specifications | |

| Center Frequency | 40.0± 1.0KHz |

| Bandwidth (-6dB) | 2.5KHz |

| Capacitance at 1KHz ±20% | 2400 pF |

| Max. Driving Voltage (cont.) | 20 Vrms |

| Total Beam Angle -6dB | 50° typical |

| Receiver Housing Material | Aluminum |

| Inspection Capabilities and Applications | Ultrasound; Medium/High Voltage Applications |

| Certifications | |

| Certifications | Certified by UL (USA) & cUL (Canada) to the following standards: 50V, 50E, 756C: Impact and Flammability, 746C & 746A-2012, 1558: Impact and Load Resistance, 508A: ANSI 508A |

| Certifications | CSA C22.2 No. 14-13, C22.2 No. 14-10, C22.2 No. 94-M91, C22.2 No.94.1-07, C22.2 No. 94.2-07 |

| Certifications | IP10 / NEMA 1 |

| Certifications | Lloyds of London Type Approval |

| Certifications | American Bureau of Shipping (ABS) |

| Certifications | DNV (Det Norske Veritas) P261.1E Maritime, Vessel and Offshore Applications |

| Certifications | IEEE C37 20.7 Type 2B, C37 20.2.a.3.6: Impact and Load |

| Certifications | IEC 62271-200, 60262271-200,60298 Appendix A, 60068-2-6:2007, 60068-2-3, 60068-2-78:2012 |

| Other | |

| Warranty | Unconditional Lifetime Warranty |

Product Resources

Recommended Products