Ultrasound Inspection Solutions

Safely Inspect Your Electrical Assets in an Energized State

Ultrasound inspection using sound ports and handheld testing devices plays a critical role when used in asset inspection and management programs. Anomalies in equipment or components of equipment may create ultrasound waves that, when detected, could alert the maintenance team that a component or machine needs to be further assessed for deterioration. The goal is to find the anomaly and determine the health of the equipment and fix it if needed before that equipment fails. Condition Based Maintenance programs allow companies to proactively detect and fix defects before costly repairs or full replacements are needed.

View MoreReal-Time Monitoring and Analysis

Enables continuous surveillance of equipment and structures, providing instant feedback and allowing for immediate action to prevent failures, enhancing operational safety and reliability.

High Sensitivity and Accuracy

Capable of detecting extremely small defects and changes in material properties, offering precise diagnostics that ensure critical components meet safety and reliability standards.

Environmentally Friendly

Operates without the need for hazardous materials or processes, making it a safe choice for both operators and the environment, aligning with sustainability goals and regulations.

Features

Enhanced Diagnostic Accuracy

Utilizes sound ports and handheld devices to accurately pinpoint the source of equipment anomalies for precise diagnostics.

Preventative Health Monitoring

Facilitates ongoing health monitoring of equipment, allowing for timely interventions and maintenance.

Minimizes Downtime

By detecting issues early, it significantly reduces the risk of unplanned downtime, enhancing operational efficiency.

Sustainability in Maintenance

Promotes a sustainable approach to maintenance by extending the life of equipment and reducing the need for resource-intensive replacements.

Ultrasound Inspection Solutions

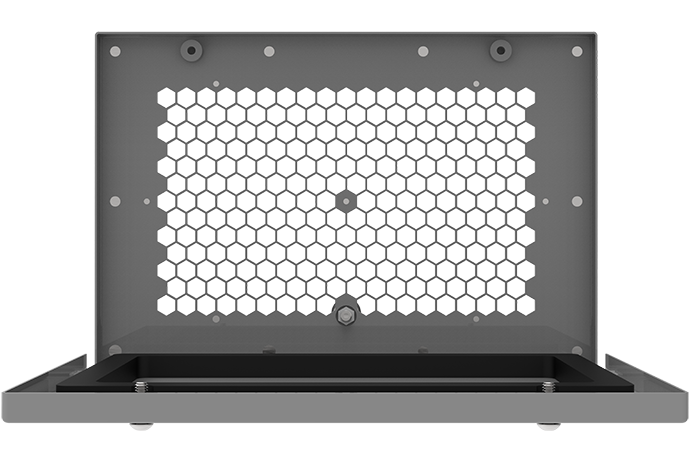

CAP-ENV-PDS Series

The Toughest and Most Reliable IR, Ultrasound & Partial Discharge Inspection Window

Starting at $ 449

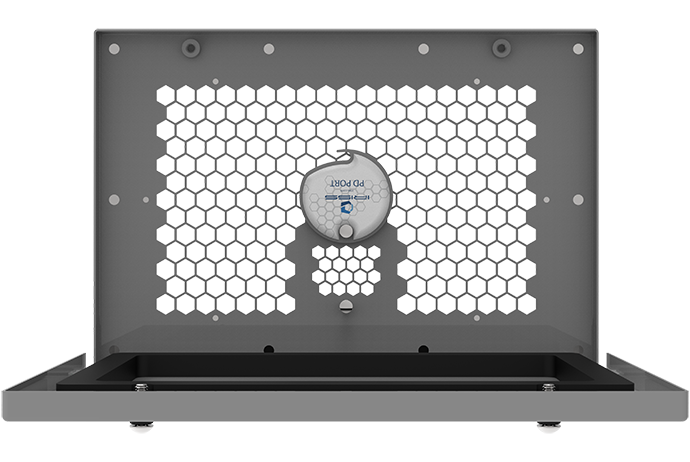

CAP-ENV-PD Series

The Toughest and Most Reliable Infrared and Ultrasound Window

Starting at $ 839

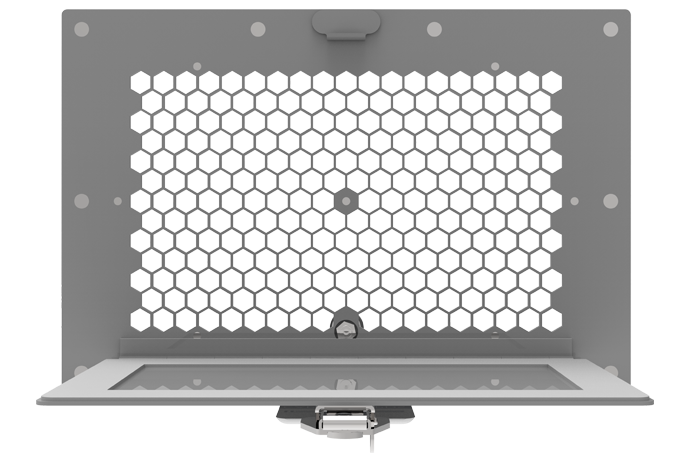

CAP-CT-PDS Series

The Most Versatile & Reliable IR, Ultrasound & Partial Discharge Inspection Window

Starting at $ 399